Navigating the world of credit requires understanding reports and bureaus; essential for financial success, impacting loan approvals and interest rates significantly today.

Credit reporting is a cornerstone of the modern financial system, influencing access to loans, credit cards, and even housing opportunities. Understanding how credit reports are generated, utilized, and maintained is crucial for every consumer. Banks and lenders rely heavily on these reports when evaluating applications, making informed decisions about risk.

These reports, compiled by consumer reporting agencies, provide a detailed history of your creditworthiness. They aren’t static documents; they evolve with your financial behavior. Knowing the three major bureaus – Equifax, Experian, and TransUnion – is the first step towards taking control of your financial future. Proactive monitoring and understanding your rights are key to a healthy credit profile.

What is a Credit Report?

A credit report is a detailed record of your credit history, compiled by credit bureaus. It contains information lenders use to assess your creditworthiness – essentially, how likely you are to repay borrowed money. This report isn’t just about whether you’ve borrowed; it details how you’ve managed credit over time.

Key components include personal identification, credit accounts (loans, credit cards), public records like bankruptcies, and a history of who has accessed your report (inquiries). Lenders “pull” these reports when you apply for credit. Understanding what’s in your report is vital, as inaccuracies can negatively impact your ability to secure loans or favorable interest rates. Regular review is highly recommended.

The Three Major Credit Bureaus

Equifax, Experian, and TransUnion are the dominant forces in credit reporting, acting as repositories of consumer credit information. These agencies gather data from lenders, creditors, and public records to create your credit reports. While they all aim to provide a comprehensive overview, information can vary between them.

This means your report might not be identical across all three bureaus, highlighting the importance of checking each one individually. Lenders often use scores and reports from multiple bureaus when making credit decisions. Understanding these agencies and their roles is crucial for managing and monitoring your credit health effectively, ensuring accuracy and addressing any discrepancies.

Equifax: Overview and Services

Equifax is one of the three major credit bureaus, collecting and maintaining financial information on millions of consumers. They provide credit reports and scores to lenders, helping them assess creditworthiness. Beyond basic reports, Equifax offers various services including credit monitoring, identity theft protection, and dispute resolution assistance.

Consumers can access their Equifax credit report for free annually through AnnualCreditReport.com. Equifax also provides tools for understanding your credit and improving your score. They’ve faced scrutiny regarding data security in the past, leading to enhanced security measures and consumer support resources. Regularly reviewing your Equifax report is a vital step in financial health.

Experian: Overview and Services

Experian is a leading global information services company and one of the big three credit bureaus in the United States. They compile credit data, providing reports and scores used by lenders to evaluate risk. Experian goes beyond traditional credit reporting, offering identity theft protection services, credit education tools, and marketing services to businesses.

Consumers can obtain a free copy of their Experian credit report annually via AnnualCreditReport.com. Experian also provides a free credit score and monitoring options. They actively work to help consumers understand and improve their credit profiles. Like other bureaus, Experian has faced data breach concerns, prompting ongoing investments in cybersecurity and consumer protection.

TransUnion: Overview and Services

TransUnion is a major credit reporting agency, completing the trio of Equifax, Experian, and themselves, vital to the US financial system. They gather and maintain credit information on over one billion individuals, providing credit reports and scores to lenders and businesses. Beyond core reporting, TransUnion offers solutions for fraud prevention, marketing, and risk management.

Consumers are entitled to a free credit report from TransUnion annually through AnnualCreditReport.com. They also provide credit monitoring and identity theft protection services, some available for a fee. TransUnion emphasizes data accuracy and offers dispute resolution processes for correcting errors on credit reports, ensuring fair credit access for all.

Components of a Credit Report

A comprehensive credit report details your credit history, serving as a financial snapshot for lenders. It’s structured into several key sections, providing a holistic view of your creditworthiness. These components include personal identification information – verifying your name, address, and employment history – ensuring accuracy is crucial.

Detailed credit accounts showcase your payment history, credit limits, and outstanding balances. Public records, like bankruptcies and judgments, are also listed. Finally, inquiries document who has accessed your report, differentiating between ‘hard’ and ‘soft’ pulls. Understanding each section empowers you to monitor and manage your credit effectively.

Personal Identification Information

This foundational section of your credit report confirms your identity, ensuring accuracy is paramount. It typically includes your full legal name, current and previous addresses, dates of birth, and Social Security number – though the last is often partially masked for security. Employment history, listing employers and positions held, is also frequently included.

Credit bureaus utilize this data to match inquiries and accounts to the correct individual. Regularly reviewing this information for errors, such as misspelled names or incorrect addresses, is vital. Any discrepancies should be promptly disputed with the reporting agency to prevent potential issues with credit applications.

Credit Accounts: History and Status

This core component details your credit card and loan accounts, forming a significant portion of your credit score. It lists each account, including the creditor’s name, account number (often partially masked), the date the account was opened, credit limits or loan amounts, current balances, and payment history.

The report showcases whether payments were made on time, late, or missed entirely. Account status – open, closed, or in collections – is also indicated. A consistent history of on-time payments demonstrates responsible credit management, positively impacting your score. Reviewing this section for inaccuracies is crucial for maintaining a healthy credit profile.

Public Records: Bankruptcies and Judgments

This section of your credit report details legal actions impacting your creditworthiness, typically remaining visible for seven to ten years. Bankruptcies, including Chapter 7, 11, or 13 filings, are prominently displayed, signaling significant financial distress. Civil judgments resulting from lawsuits, such as unpaid debts, also appear, indicating a legal obligation to pay.

Tax liens, filed by government entities for unpaid taxes, are another type of public record. While these records negatively affect your score, accurate reporting is vital. Regularly checking this section ensures no errors exist, and disputing inaccuracies promptly is essential for protecting your financial reputation.

Inquiries: Hard vs. Soft Pulls

Credit inquiries appear on your report when a lender checks your credit, but not all inquiries are created equal. “Hard inquiries” occur when applying for credit – loans or credit cards – and can slightly lower your score, especially multiple applications within a short timeframe. These signal potential risk to lenders.

“Soft inquiries,” however, have no impact on your score. These happen during background checks, pre-approved credit offers, or when you check your own credit report. Understanding this distinction is crucial; routinely monitoring your report via soft pulls won’t harm your credit, allowing you to identify potential fraud or errors.

Understanding Your Credit Score

Your credit score is a three-digit number summarizing your creditworthiness, heavily influencing lending decisions. It’s not simply about having credit; it’s about how you manage it. Lenders use scores to assess risk – a higher score indicates a reliable borrower, often unlocking better interest rates and loan terms.

While numerous scoring models exist, FICO and VantageScore are the most prevalent. These models analyze information from your credit report, weighting factors like payment history, amounts owed, length of credit history, credit mix, and new credit applications. Understanding these components empowers you to improve your score proactively.

FICO Score: The Most Widely Used Model

The FICO Score remains the gold standard in credit scoring, utilized by a vast majority of lenders nationwide. Developed by the Fair Isaac Corporation, it analyzes data from the three major credit bureaus – Equifax, Experian, and TransUnion – to generate a score ranging from 300 to 850.

Payment history carries the most weight (35%), followed by amounts owed (30%), length of credit history (15%), credit mix (10%), and new credit (10%). Different versions of the FICO Score exist, tailored for specific lending purposes, like auto loans or mortgages. Understanding its components is crucial for effective credit management.

VantageScore: An Alternative Scoring Model

VantageScore is a credit scoring model developed collaboratively by the three major credit bureaus – Equifax, Experian, and TransUnion – as a competitor to FICO. It aims to provide a more consistent and accessible scoring method, particularly for consumers with limited credit history.

VantageScore 3.0 and 4.0 are the most current versions, utilizing a similar scoring range of 300-850. While weighting factors differ slightly from FICO, payment history remains highly influential. VantageScore often considers more data points, potentially scoring individuals FICO might not. Lenders are increasingly adopting VantageScore, making it vital to understand alongside your FICO score.

Accessing Your Credit Reports

Regularly checking your credit reports is crucial for maintaining financial health and identifying potential errors or fraudulent activity. By law, you are entitled to a free credit report from each of the three major bureaus – Equifax, Experian, and TransUnion – annually.

AnnualCreditReport.com is the official website authorized to provide these free reports. Beyond this, numerous credit monitoring services offer ongoing access to your reports and scores, often for a monthly fee. These services typically include alerts for changes to your credit profile, providing an extra layer of security and proactive monitoring.

AnnualCreditReport.com: Free Reports

AnnualCreditReport.com is the only website authorized by federal law to provide your free annual credit reports. It’s a centralized service allowing you to request reports from Equifax, Experian, and TransUnion, all in one place. You can choose to receive all three reports at once, or stagger them throughout the year for continuous monitoring.

This service is truly free; be wary of imitators offering “free” reports with hidden fees or requiring credit card details upfront. Accessing your reports through AnnualCreditReport.com doesn’t impact your credit score – these are considered “soft inquiries.” Utilize this valuable resource to stay informed about your credit health.

Credit Monitoring Services: Paid Options

Numerous credit monitoring services offer more comprehensive features than free annual reports, but come with a monthly fee. These services typically provide daily credit updates, alerts for changes to your credit file (like new accounts or inquiries), and often include identity theft protection features.

Popular providers include MyFICO, Experian IdentityWorks, and LifeLock. They often offer credit scores, reports from all three bureaus, and even insurance reimbursement for identity theft-related expenses. Carefully evaluate your needs and compare pricing before subscribing, ensuring the benefits justify the cost.

Disputing Errors on Your Credit Report

Discovering inaccuracies on your credit report is surprisingly common, and you have the right to dispute them. The process involves contacting the credit bureau (Equifax, Experian, or TransUnion) in writing, detailing the error and providing supporting documentation. Each bureau has a specific address for disputes, readily available on their websites.

The credit bureau is legally obligated to investigate within 30 days. They’ll contact the creditor to verify the information. If the error is confirmed, it must be corrected. If not, you can add a statement to your report explaining your side of the story, ensuring future lenders see your explanation.

The Dispute Process with Credit Bureaus

Initiating a dispute requires a clear, concise letter sent via certified mail with return receipt requested to each relevant credit bureau. Include your full name, address, Social Security number, and a detailed description of the inaccurate item. Attach copies (never originals!) of supporting documents – statements, court records, or payment confirmations.

The bureau has 30 days to investigate, potentially extending to 45 if you submit additional information. They’ll forward your dispute to the data furnisher (creditor). You’ll receive a written response outlining the investigation’s outcome. If the error remains, you can request a reinvestigation or file a complaint with the Consumer Financial Protection Bureau (CFPB).

Documentation Required for Disputes

Successful dispute resolution hinges on providing compelling evidence. For inaccurate account information, submit copies of statements demonstrating correct payment history or account closure. If disputing a public record like bankruptcy, include relevant court documents – petitions, discharge orders, or judgments. Identity theft requires a police report and an Identity Theft Affidavit.

Avoid sending original documents; copies are sufficient and protect your sensitive information. Clearly label each document, referencing the specific item on your credit report it supports. Organize your documentation logically for easy review by the credit bureau. Thorough preparation significantly increases your chances of a favorable outcome.

Buy Now, Pay Later (BNPL) and Credit Reporting

The impact of Buy Now, Pay Later (BNPL) on credit reports is evolving. Historically, many BNPL providers didn’t report to the major credit bureaus, meaning on-time payments weren’t boosting scores, nor were missed ones damaging them. However, this is changing as BNPL gains prominence.

Affirm has begun reporting to Experian, marking a significant shift. Reporting practices vary; some providers report only negative information, while others report both positive and negative. Understanding a provider’s policy is crucial. BNPL can now influence credit decisions, so responsible usage is paramount.

How BNPL Impacts Credit Reports

BNPL’s influence on credit reports is becoming increasingly significant. Previously, a lack of reporting meant BNPL activity was often invisible to credit bureaus, offering a risk-free credit-building (or damaging) experience. Now, with providers like Affirm reporting to Experian, timely payments can positively affect your credit score.

Conversely, missed BNPL payments can negatively impact your credit. The extent of the impact depends on the reporting practices of the specific provider and the severity of the delinquency. It’s vital to manage BNPL plans responsibly, treating them like traditional credit accounts to avoid potential harm.

Reporting Practices of BNPL Providers

BNPL reporting isn’t uniform; practices vary significantly between providers. Affirm, a prominent player, has initiated reporting to Experian, focusing on positive payment history to help consumers build credit. Other providers may report only negative information, such as defaults, to collection agencies, impacting scores adversely.

This inconsistency creates a fragmented credit picture. Some BNPL loans may appear on your credit report, while others remain invisible. Understanding a provider’s reporting policy before using their service is crucial for managing your credit effectively. Transparency in reporting is slowly increasing, but remains a key area for consumer awareness.

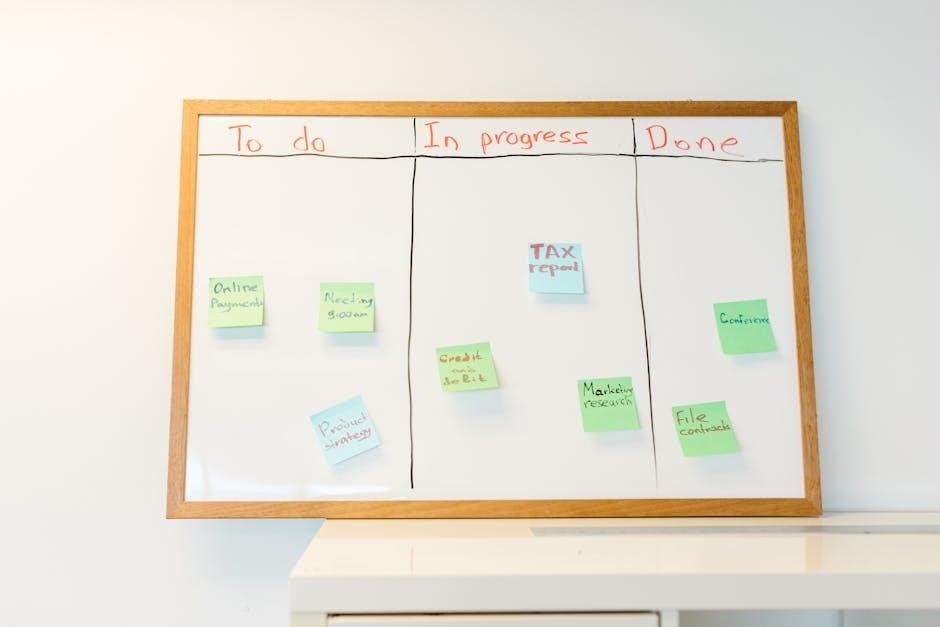

Improving Your Credit Score

Boosting your credit score requires consistent, positive financial habits. Payment history carries the most weight; always pay bills on time, every time. Maintaining low credit utilization – the amount of credit used versus available – is also vital, ideally below 30%. A longer credit history generally improves scores, so avoid closing old accounts unnecessarily.

Diversifying credit types can also be beneficial. A mix of credit cards, installment loans, and other credit products demonstrates responsible credit management; Regularly reviewing your credit report for errors and disputing inaccuracies is crucial for ensuring an accurate score;

Payment History: The Most Important Factor

Your payment history is the single most influential element in determining your credit score. Consistently paying bills on time demonstrates reliability to lenders, building trust and showcasing responsible financial behavior. Even one late payment can negatively impact your score, potentially for years.

This includes all types of credit accounts: credit cards, loans, and lines of credit. Setting up automatic payments or reminders can help ensure timely payments. Prioritizing on-time payments over paying down balances quickly is often the most effective strategy for improving your creditworthiness.

Credit Utilization: Keeping Balances Low

Credit utilization, the amount of credit you’re using compared to your total credit limit, is a crucial scoring factor. Experts generally recommend keeping your credit utilization below 30%, and ideally below 10%, to demonstrate responsible credit management.

High credit utilization signals potential financial strain to lenders. Even if you pay your bills on time, maxing out credit cards can lower your score. Strategies include paying down balances frequently, requesting credit limit increases (without increasing spending), and spreading purchases across multiple cards.

Length of Credit History: Building a Solid Record

The length of your credit history significantly impacts your credit score, demonstrating your ability to manage credit over time. A longer history generally leads to a higher score, as it provides lenders with more data to assess your reliability.

For those new to credit, establishing a positive record is key. Start with a secured credit card or become an authorized user on a responsible account holder’s card. Avoid opening numerous accounts simultaneously, as this can appear risky. Patience is vital; a strong credit history takes time to build and maintain consistently.

Protecting Your Credit Report

Safeguarding your credit report is crucial in today’s digital age, protecting against identity theft and fraudulent activity. Proactive measures can minimize risks and maintain your financial well-being.

Consider credit monitoring services, which alert you to changes in your credit file. Regularly review your reports for any unauthorized accounts or inaccuracies. A credit freeze restricts access to your report, preventing new credit applications without your explicit consent. Be vigilant about phishing scams and secure your personal information online. Promptly report any suspected fraud to the credit bureaus and relevant authorities.

Identity Theft and Credit Monitoring

Identity theft poses a significant threat to your financial health, potentially causing substantial damage to your credit report. Credit monitoring services act as an early warning system, alerting you to suspicious activity like new account openings or address changes.

These services scan your credit reports for red flags and notify you promptly. While many offer basic monitoring for free, comprehensive plans with identity theft insurance and restoration assistance are available for a fee. Regularly reviewing your credit reports, even without a monitoring service, is vital. Be cautious about sharing personal information and secure your online accounts with strong passwords.

Freezing Your Credit: A Security Measure

A credit freeze, also known as a security freeze, is a powerful tool to prevent identity theft and unauthorized credit access. When you freeze your credit, it restricts access to your credit report, making it very difficult for someone to open new accounts in your name.

This doesn’t affect your existing credit cards or loans, nor does it impact your credit score. You can temporarily lift the freeze when applying for legitimate credit. Freezing and unfreezing are now free with all three major credit bureaus – Equifax, Experian, and TransUnion – offering increased control and peace of mind regarding your financial information.